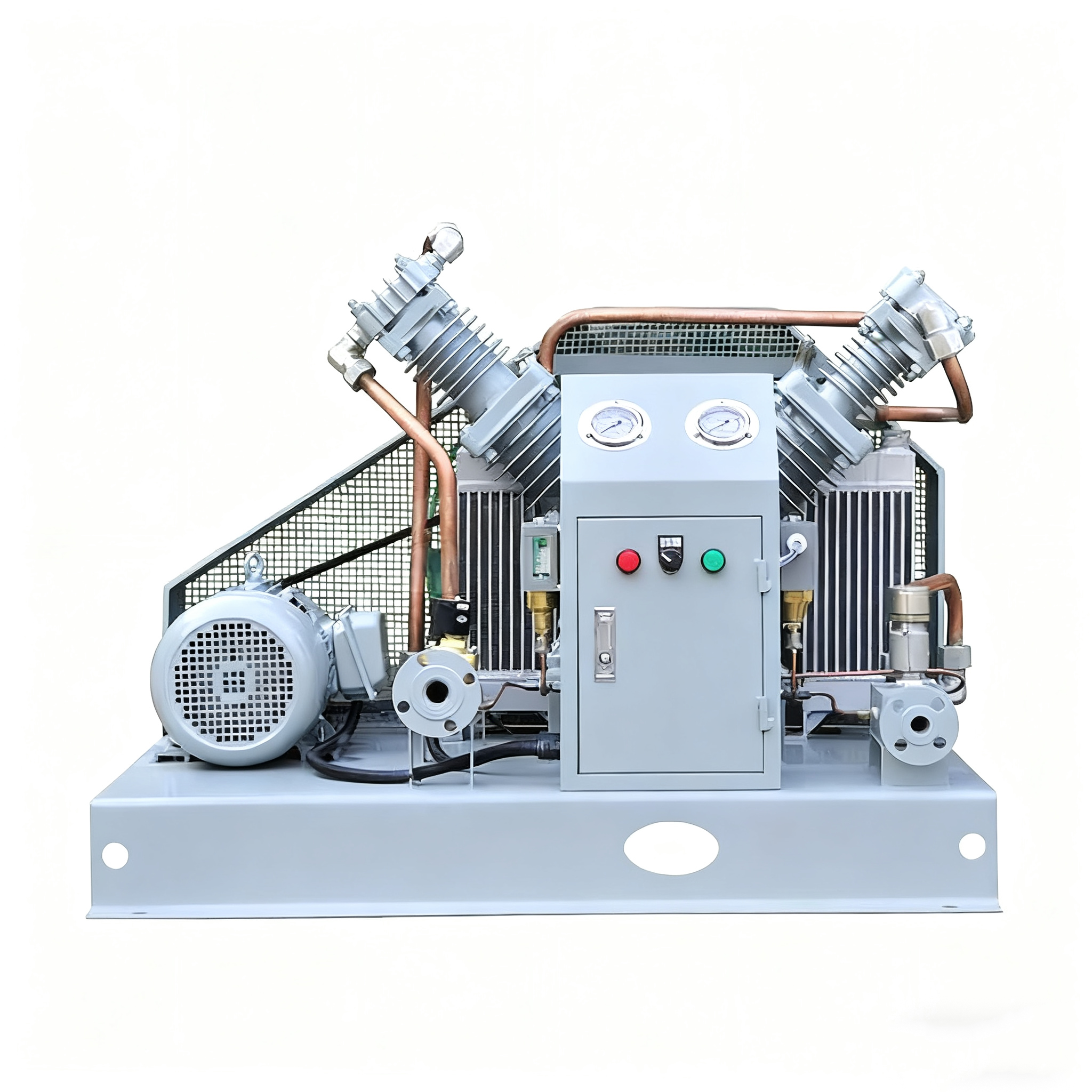

Oil-free low-pressure nitrogen compressor

1.Boosts low-pressure nitrogen (7–10 kg) to 15–45 kg for applications such as laser cutting, chemical plants, and tyre manufacturing.

2.Completely oil-free, environmentally friendly, and pollution-free, requiring no oil lubrication.

3.Friction seals (piston and guide rings) made of self-lubricating materials, ensuring no impact on gas composition.

4.Simple, reliable structure with consistent nitrogen purity from inlet to outlet and easy operation.

- Overview

- Product Advantages

- Technical Parameters

- FAQ

PUFCO nitrogen compressors are primarily employed for boosting low-pressure nitrogen. Typically, nitrogen produced by PSA or membrane nitrogen generators operates at pressures of 7-10 kg, requiring compression to 15-45 kg for applications such as nitrogen shielding in laser cutting machines, nitrogen protection in chemical plants, and nitrogen shielding within the tyre manufacturing industry.

Completely oil-free, environmentally friendly and pollution-free, requiring no oil lubrication.

Friction seals such as piston rings and guide rings are manufactured from special self-lubricating materials that do not affect gas composition.

1. The entire compression system operates without thin oil lubrication, eliminating any possibility of oil contacting high-pressure, high-purity nitrogen.

2. The system features a simple mechanical structure, facilitating straightforward control and operation.

3. No contamination of the compressed gas medium occurs, with identical nitrogen purity at both the compressor inlet and outlet.

| Model | Inlet Pressure (barg) |

Outlet Pressure (barg) |

Nominal Volume Flow (Nm³/h) |

Motor Power (kW) | Inlet | Outlet | Cooling Method | Net Weight (kg) |

L×W×H(mm) |

| PWW-80/5-50 | 5 | 50 | 80 | 15 | DN40 | DN15 | Air | 660 | 1400*950*1100 |

| PWW-100/5-25 | 5 | 25 | 100 | 15 | DN40 | DN20 | Air | 600 | 1450*800*1150 |

| PWW-100/6-60 | 6 | 50 | 100 | 18.5 | DN40 | DN15 | Air | 600 | 1400*920*1200 |

| PWW-100/5-50 | 5 | 50 | 100 | 18.5 | DN40 | DN25 | Air | 600 | 1400*950*1100 |

| PWW-120/5-40 | 5 | 40 | 120 | 18.5 | DN40 | DN25 | Air | 600 | 1400*950*1200 |

| PWW-120/5-25 | 5 | 25 | 120 | 15 | DN40 | DN20 | Air | 650 | 1400*950*1200 |

| PWW-120/5-70 | 5 | 70 | 120 | 22 | DN40 | DN15 | Air | 950 | 1700*950*1500 |

| PWW-150/6-25 | 6 | 25 | 2.5 | 18.5 | DN40 | DN25 | Air | 740 | 1660*950*1250 |

| PWW-150/5-30 | 5 | 30 | 150 | 18.5 | DN40 | DN25 | Air | 850 | 1700*950*1300 |

| PWW-180/5-25 | 5 | 25 | 180 | 22 | DN40 | DN25 | Air | 850 | 1700*1150*1050 |

| PWW-180/5-10 | 5 | 10 | 180 | 11 | DN40 | DN25 | Air | 460 | 1450**850*950 |

| PWW-200/5-15 | 5 | 15 | 200 | 18.5 | DN50 | DN32 | Air | 520 | 1700*950*1200 |

| PWW-200/5-25 | 5 | 25 | 200 | 22 | DN40 | DN25 | Air | 680 | 1850*950*1200 |

| PWW-350/5-10 | 5 | 10 | 350 | 18.5 | DN50 | DN40 | Air | 620 | 1700*950*1300 |

| PWW-500/6-10 | 6 | 10 | 500 | 18.5 | DN65 | DN50 | water | 1850 | 2500*1550*1800 |

| PZW-1/5-25 | 5 | 25 | 1 | 1.1 | DN15 | DN15 | Air | 140 | 500*350*400 |

| PZW-3/5-10 | 5 | 10 | 3 | 1.1 | DN15 | DN15 | Air | 120 | 800*600*700 |

| PZW-5/5-10 | 5 | 10 | 5 | 1.5 | DN15 | DN15 | Air | 200 | 1000*750*860 |

| PZW-5/5-15 | 5 | 15 | 5 | 1.5 | DN25 | DN15 | Air | 200 | 1000*700*950 |

| PZW-10/4-16 | 4 | 16 | 10 | 2.2 | DN20 | DN15 | Air | 200 | 1070*750*900 |

| PZW-20/5-15 | 5 | 15 | 20 | 2.2 | DN25 | DN15 | Air | 280 | 1000*820*950 |

| PVW-10/5-25 | 5 | 25 | 10 | 2.2 | DN25 | DN15 | Air | 300 | 1000*800*950 |

| PVW-10/5-30 | 5 | 30 | 10 | 2.2 | DN25 | DN15 | Air | 340 | 1100*800*900 |

| PVW-15/5-25 | 5 | 25 | 15 | 3 | DN25 | DN15 | Air | 300 | 1100*820*950 |

| PVW-20/6-30 | 6 | 30 | 20 | 4 | DN25 | DN15 | Air | 300 | 1100*750*950 |

| PVW-20/5-30 | 5 | 30 | 20 | 4 | DN25 | DN15 | Air | 340 | 1100*700*950 |

| PVW-30/5-20 | 5 | 20 | 30 | 4 | DN25 | DN15 | Air | 300 | 1100*720*850 |

| PVW-40/5-15 | 5 | 15 | 40 | 4 | DN25 | DN15 | Air | 340 | 1100*850*950 |

| PVW-40/5-40 | 5 | 40 | 40 | 7.5 | DN25 | DN15 | Air | 380 | 1200*820*950 |

| PVW-60/6-25 | 6 | 25 | 60 | 7.5 | DN25 | DN15 | Air | 420 | 1100*820*950 |

| PVW-50/5-30 | 5 | 30 | 50 | 7.5 | DN25 | DN15 | Air | 460 | 1200*820*950 |

| PVW-50/5-20 | 5 | 20 | 50 | 5.5 | DN25 | DN15 | Air | 360 | 1100*820*950 |

| PVW-150/5-15 | 5 | 15 | 150 | 11 | DN40 | DN25 | Air | 480 | 1400*820*950 |

| PZW-300/6-80 | 0.6 | 8 | 300 | 55 | DN50 | DN20 | water | 2800 | 2500*1850*2050 |

| PZW-300/5-80 | 0.5 | 8 | 300 | 55 | DN65 | DN25 | water | 3000 | 2500*1850*2150 |

| PZW-400/5-40 | 0.5 | 4 | 400 | 55 | DN65 | DN25 | water | 2850 | 2500*1850*2150 |

| PZW-400/6-50 | 0.6 | 5 | 400 | 55 | DN65 | DN32 | water | 3000 | 2500*1850*2150 |

| PZW-500/6-60 | 0.6 | 6 | 500 | 75 | DN80 | DN32 | water | 3000 | 2500*1850*2150 |

| PZW-600/6-30 | 0.6 | 3 | 600 | 55 | DN80 | DN32 | water | 3000 | 2500*1700*2200 |

| PZW-600/10-35 | 1 | 3.5 | 600 | 55 | DN65 | DN40 | Air | 3800 | 2500*1850*2150 |

| PZW-700/5-30 | 0.5 | 3 | 700 | 75 | DN80 | DN40 | water | 3200 | 2600*1850*2200 |

| PZW-800/6-30 | 0.6 | 3 | 800 | 90 | DN100 | DN50 | water | 3600 | 2650*1850*2200 |

| PZW-1000/5-12 | 0.5 | 1.2 | 1000 | 55 | DN100 | DN65 | water | 4400 | 2550*1750*2250 |

| PZW-1800/6-13 | 0.6 | 1.3 | 1800 | 90 | water | 3600 | 2500*1850*2300 | ||

| PSW-180/6-60 | 0.6 | 6 | 180 | 30 | water | 1200 | 1850*1200*1400 | ||

| PSW-180/5-80 | 0.5 | 8 | 180 | 37 | water | 1300 | 1850*1250*1650 | ||

| PSW-300/6-30 | 0.6 | 3 | 300 | 37 | DN50 | DN32 | water | 1350 | 1850*1200*1500 |

| PSW-300/5-25 | 0.5 | 2.5 | 300 | 37 | DN65 | DN25 | water | 1250 | 1850*1200*1500 |

| PSW-360/7-25 | 0.7 | 2.5 | 360 | 37 | DN50 | DN32 | water | 1400 | 1850*1200*1500 |

| PSW-400/5-20 | 0.5 | 2 | 400 | 37 | water | 1300 | 1850*1250*1750 | ||

| PSW-400/6-30 | 0.6 | 3 | 400 | 45 | DN65 | DN32 | water | 1250 | 1900*1250*1500 |

| PSW-500/5-10 | 0.5 | 1 | 500 | 30 | water | 1250 | 1850*1200*1500 | ||

| PSW-600/5-10 | 0.5 | 1 | 600 | 30 | water | 1150 | 1850*1300*1700 | ||

| PSW-600/5-12 | 0.5 | 1.2 | 600 | 37 | water | 1150 | 1850*1200*1650 | ||

| PSW-1000/5-10 | 0.5 | 1 | 1000 | 45 | DN100 | DN65 | water | 1200 | 2550*1750*2250 |

Frequently Asked Questions

-

Q1: Are you a manufacturer or trading company? ▼A1: We are professional manufacturer with big modern factory in Shanghai, China. Both OEM & ODM service can be accepted.

-

Q2: Warranty terms of your machine? ▼A2: One year for the whole machine and two years for screw air end, except consumable spare parts. We provide technical support according to your needs.

-

Q3: Will you provide some spare parts of the machines? ▼A3: Yes. We provide spare parts for daily maintenance.

-

Q4: What voltage can you provide? ▼A4: We can support 220V/380V/400V/415V/440V/480V/570V/600V/1000V 50HZ/60HZ. Send your requirements to our sales manager and we will customize it for you.

-

Q5: How long will you take to arrange production? ▼A5: Delivery of standard goods within 7-10 working days, customization takes about 30 days.

-

Q6: How to pay? ▼A6: T/T, L/C, D/P, Western Union, Apple pay, Google pay, PAYPAL, Credit Card and so on. We also accept USD, RMB, EUR and other currencies.

-

Q7: Can you accept OEM/ODM orders? ▼A7: Yes, we have a professional design team, OEM/ODM orders are very welcome.

CN

CN