|

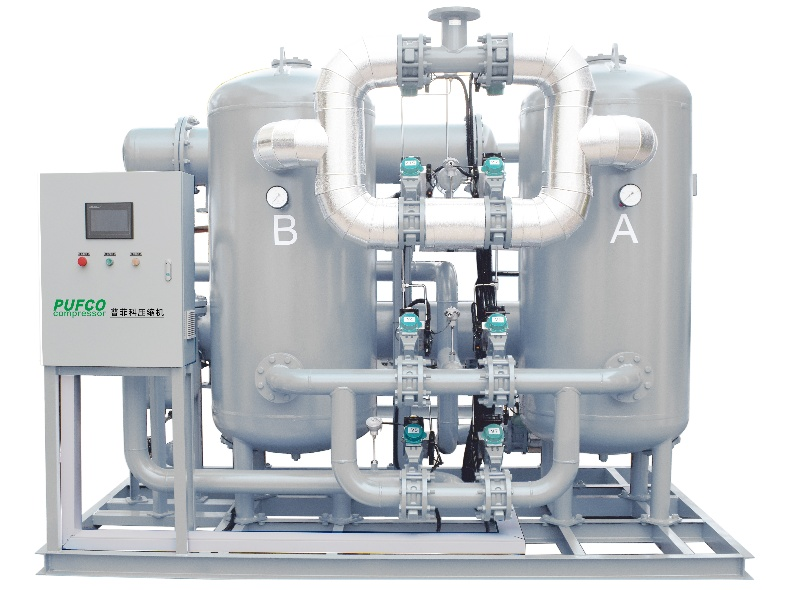

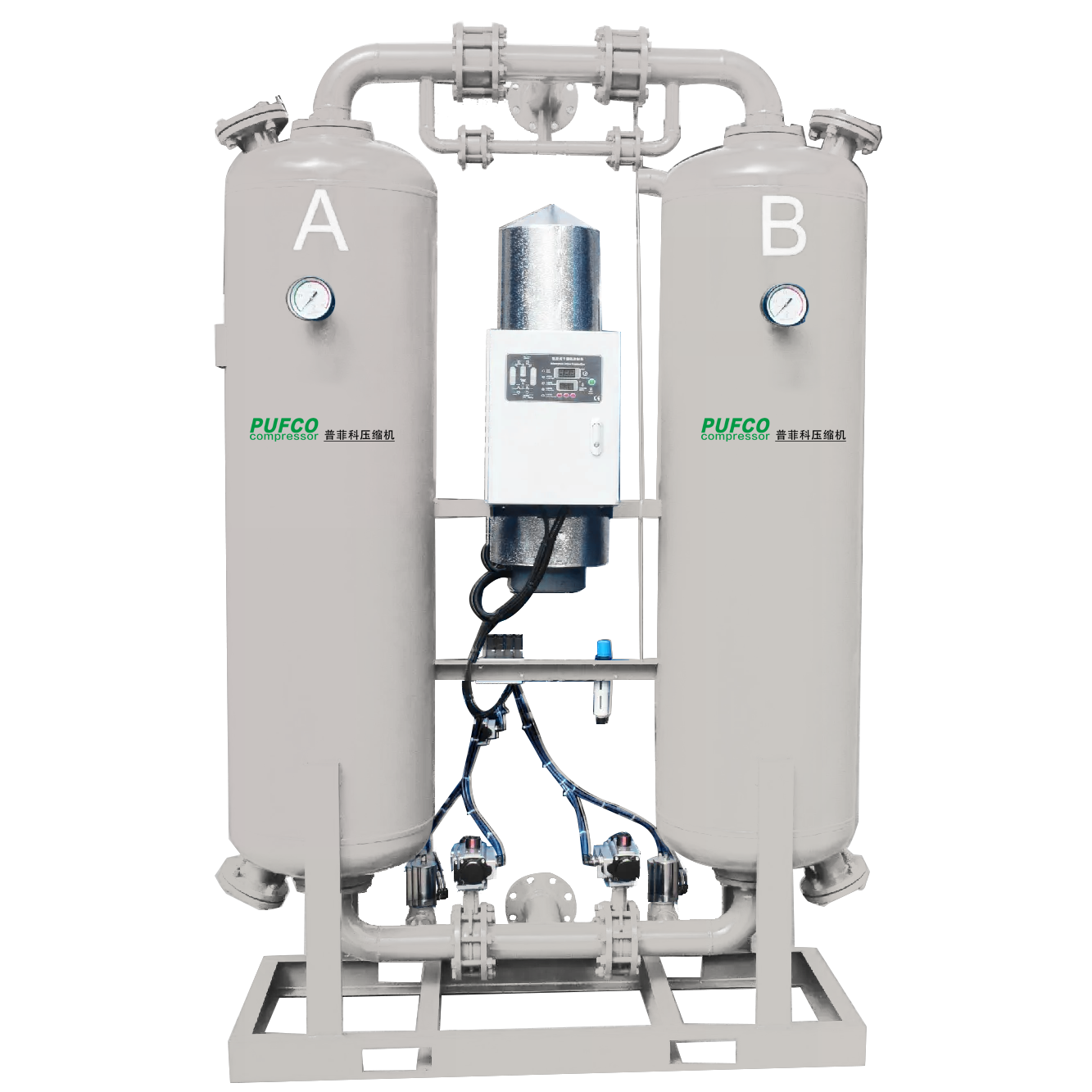

Our full-range air post-treatment lineup is customized for air compressor users, covering high-temperature refrigerated dryers, energy-saving adsorption dryers (zero/micro purge blower-heated, zero/micro purge compression-heated, zero purge rotary models), precision filters, and durable stainless/carbon steel air receivers—all engineered for industrial reliability and energy efficiency. For food & pharmaceutical sectors, it meets GMP standards with food-grade filters, achieving oil-free, dust-free air to avoid secondary contamination. Core advantages include zero/micro air loss (slashing operational costs), compression heat reuse (enhancing energy efficiency), and strong high-temperature adaptability. We provide customized systems based on your air compressor’s parameters and industry demands—ideal for machinery manufacturing, automotive parts, textiles, food & pharma, and electronics. Trust our systems for clean, dry air and seamless integration. |