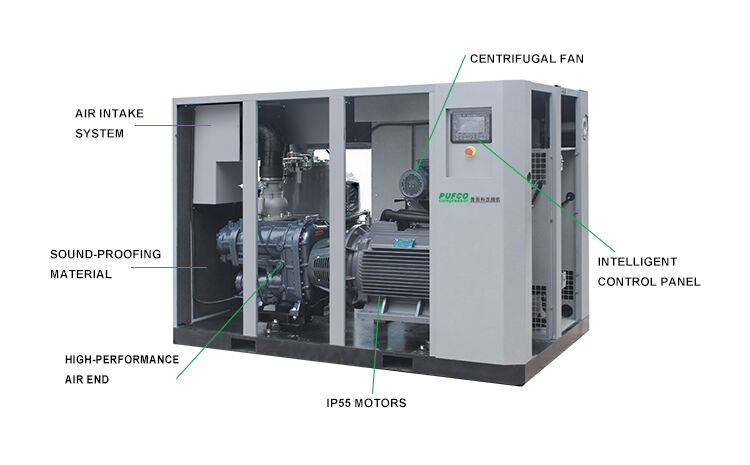

Two-stage permanent magnet variable frequency air compressor

Power:22KW-250KW

Working Pressure:0.75Mpa-1.3Mpa

Air Capacity:3.2³/min-54m³/min

Voltage:380V, 110V, 220V, ets.

- Overview

- Product Advantages

- Technical Parameters

- FAQ

High quality Air End

Adopting innovative 5:6 asymmetric rotor tooth profile, the core components feature high precision and excellent stability. Service life is extended by over 30%, reducing replacement costs for enterprises.

Material

Piping system uses 304 stainless steel, offering strong corrosion and aging resistance. Service life doubles compared to carbon steel models, ideal for chemical, food processing industries.

Control system

Dedicated intelligent control system with multi-channel pressure/temperature sensors monitors operation in real-time. 20% higher control precision than traditional systems, with user-friendly interface and energy-saving performance.

Centrifugal Fans

New independent radial cooling fan with special cooler achieves 40% higher cooling efficiency. 35% higher wind pressure, ≤65dB lower noise, and 25% less energy consumption than conventional axial fans.

Compressor screw

The larger the screw, the more stable the operation, the lower the failure rate, the longer the service life, the lower the heat dissipation, and the lower the operating costs.

PUFCO Screw use Customised 5:6 type large-size low-speed screw .

Other Screw USE High-speed air end with small screw

Bearings

Bearings are core spare parts for air compressors and play a decisive role in determining the maximum design life of air compressors.

PUFCO USE SKF heavy-duty bearings are used, with a design life of 200,000 hours.

The use of medium- and low-grade bearings results in a relatively short service life.

Coolers

Suspended radiators eliminate thermal stress and increase the service life of coolers. Lower temperatures significantly improve the operating conditions of air compressors, increase operational stability, and extend service life.

PUFCO Cooler 1.5 times larger than conventional models, with low fouling coefficient. Suspended separation arrangement, capable of withstanding maximum operating temperatures of 46 degrees.

The cooler is small in size and has poor cooling efficiency, resulting in increased maintenance work and shortened coolant life.

Electrical components

High-quality electrical components can reduce current surges during start-up (poor-quality contactors may generate instantaneous high currents, accelerating motor insulation ageing). At the same time, they can monitor abnormal loads more accurately and cut off the power supply in a timely manner to prevent wear and tear on the main unit due to overload.

Brands such as ABB, Siemens, and Schneider Electric offer high reliability.

Using mid- to low-end electrical components results in lower costs.

Using mid- to low-end electrical components results in lower costs.Frequency converter

High-quality electrical components can reduce current surges during start-up (poor-quality contactors may generate instantaneous high currents, accelerating motor insulation ageing). At the same time, they can monitor abnormal loads more accurately and cut off the power supply in a timely manner to prevent wear and tear on the main unit due to overload.

PUFCO customised anti-interference frequency converter with 1.5 times redundancy.

Using mid- to low-end electrical components results in lower costs.

Using mid- to low-end electrical components results in lower costs.| Model | Power (KW) | Working Pressure (Mpa) | Displacement (m³/min) | Overall Dimension (mm) | Weight (kg) | Outlet Pipe Diameter | ||

|---|---|---|---|---|---|---|---|---|

| Length (L) | Width (W) | Height (H) | ||||||

| FVA-22Ⅱ | 22KW | 0.75 | 4.3 | 1560 | 1000 | 1160 | 450 | RP1 |

| 0.85 | 4.1 | 1560 | 1000 | 1160 | 450 | RP1 | ||

| 1.05 | 3.5 | 1560 | 1000 | 1160 | 450 | RP1 | ||

| 1.3 | 3.2 | 1560 | 1000 | 1160 | 450 | RP1 | ||

| FVA-30Ⅱ | 30KW | 0.75 | 6.5 | 1750 | 1150 | 1290 | 650 | RP1 1/2 |

| 0.85 | 6.1 | 1750 | 1150 | 1290 | 650 | RP1 1/2 | ||

| 1.05 | 4 | 1750 | 1150 | 1290 | 650 | RP1 1/2 | ||

| 1.3 | 3.7 | 1750 | 1150 | 1290 | 650 | RP1 1/2 | ||

| FVA-37Ⅱ | 37KW | 0.75 | 7.7 | 1750 | 1150 | 1290 | 650 | RP1 1/2 |

| 0.85 | 7.3 | 1750 | 1150 | 1290 | 650 | RP1 1/2 | ||

| 1.05 | 6.1 | 1750 | 1150 | 1290 | 650 | RP1 1/2 | ||

| 1.3 | 5.8 | 1750 | 1150 | 1290 | 650 | RP1 1/2 | ||

Frequently Asked Questions

-

Q1: Are you a manufacturer or trading company? ▼A1: We are professional manufacturer with big modern factory in Shanghai, China. Both OEM & ODM service can be accepted.

-

Q2: Warranty terms of your machine? ▼A2: One year for the whole machine and two years for screw air end, except consumable spare parts. We provide technical support according to your needs.

-

Q3: Will you provide some spare parts of the machines? ▼A3: Yes. We provide spare parts for daily maintenance.

-

Q4: What voltage can you provide? ▼A4: We can support 220V/380V/400V/415V/440V/480V/570V/600V/1000V 50HZ/60HZ. Send your requirements to our sales manager and we will customize it for you.

-

Q5: How long will you take to arrange production? ▼A5: Delivery of standard goods within 7-10 working days, customization takes about 30 days.

-

Q6: How to pay? ▼A6: T/T, L/C, D/P, Western Union, Apple pay, Google pay, PAYPAL, Credit Card and so on. We also accept USD, RMB, EUR and other currencies.

-

Q7: Can you accept OEM/ODM orders? ▼A7: Yes, we have a professional design team, OEM/ODM orders are very welcome.

CN

CN