- Overview

- Technical Parameters

- Product Features

- FAQ

Working Principle

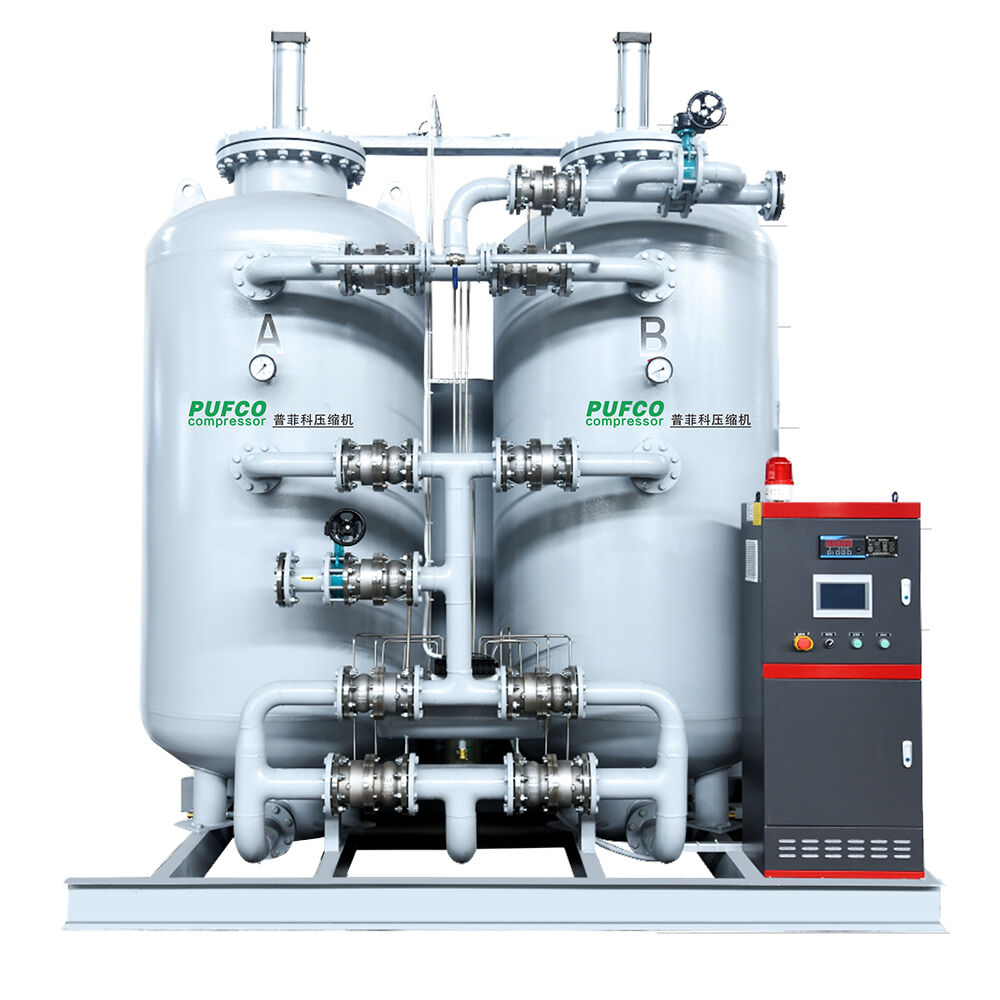

The main unit of the molecular sieve nitrogen generator comprises two adsorption towers. When clean compressed air enters Tower A at the inlet end and flows through the carbon molecular sieve towards the outlet end, O₂, CO₂, and H₂O are adsorbed. The product nitrogen gas flows out from the adsorption tower outlet end. After a period of time, the carbon molecular sieve within Tower A becomes saturated with adsorbed substances. At this point, Tower A automatically ceases adsorption. Compressed air then flows into Tower B to adsorb oxygen and produce nitrogen, whilst simultaneously regenerating the molecular sieves within Tower A.

Molecular sieve regeneration is achieved by rapidly depressurising the adsorption tower to atmospheric pressure, thereby desorbing the adsorbed O₂, CO₂, and H₂O. The two towers alternately perform adsorption and regeneration cycles, completing oxygen-nitrogen separation and enabling continuous nitrogen output.

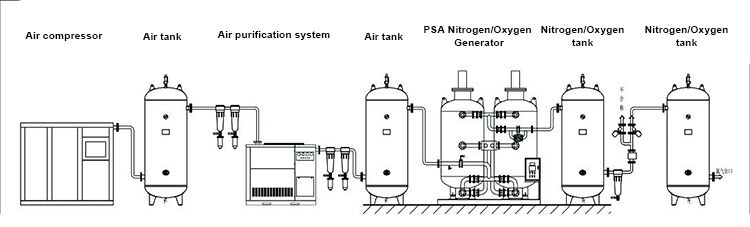

System Flow

The pressure swing adsorption nitrogen generator comprises an air compressor, compressed air buffer tank, air purification system, air process tank, nitrogen generator main unit, nitrogen process tank, electrical control system, and nitrogen storage tank.

Depending on operating conditions, it may integrate with liquid nitrogen systems. Liquid ammonia is typically employed for peak compensation, while PSA ammonia generation provides routine supply.

01 Carbon Molecular Sieve

PUFCO can select the best products according to the user's working conditions. It is characterized by stable performance, high recovery rate and long service life (more than 8 years of normal use). It can be equipped with carbon molecular sieve from Germany BF company, Japan Takeda, Japan Iwatani and other companies.

02 Pneumatic Valve

Valve selection of Germany GEMU, Germany Bürkert,Germany DREHMO GmbH,Qingdao Jingrui and other high-quality pneumatic angle seat valves and pipeline valves, the valve body average trouble-free work in 3 million times, the failure rate reduced by more than 50%.

03 Auxiliary device

The pneumatic components are adopted from Taiwan Airtac, Japan SMC and American ASCO series; solenoid valves with action times up to 1,000,000 times without leakage; and reliable air source treatment components.

04 Process Instrumentation

Measurement accuracy up to 0.01%; reliable built-in imported electrode life greatly extended, can work continuously and reliably for more than 3 years, no need to replace the oxygen electrode.

05 Flowmeter

Carefully selected flowmeter products, stable quality, reliable performance, continuous trouble-free operation for more than three years.

06 Control system

Programmable controller using Germany Siemens PLC.

07 Air Compressor System

Adopting IP54 protection grade asynchronous industrial frequency motor, compared with IE2 motor, it has higher efficiency, fewer failure points and longer life. High power with two-stage compression air end, low noise and stable air supply.

| NAME | Model | Purities | Air consumption (Nm³/min) |

Nitrogen production (Nm³/h) |

| PSA Nitrogen Generator | FAZD95 | 95% | 0.88–116.96 | 30–4000 |

| PSA Nitrogen Generator | FAZD97 | 97% | 0.96–128.65 | 30–4000 |

| PSA Nitrogen Generator | FAZD98 | 98% | 1.1–136.2 | 30–4000 |

| PSA Nitrogen Generator | FAZD29 | 99% | 0.82–122.81 | 20–3000 |

| PSA Nitrogen Generator | FAZD295 | 99.50% | 0.85–105.99 | 20–2500 |

| PSA Nitrogen Generator | FAZD39 | 99.90% | 0.53–94.74 | 10–1800 |

| PSA Nitrogen Generator | FAZD49 | 99.99% | 0.73–87.72 | 10–1200 |

| PSA Nitrogen Generator | FAZD59 | 99.999% | 0.92–73.68 | 10–800 |

| Note: Contact us and we will provide you with detailed parameters as well as an exclusive offer. | ||||

Energy-Saving Technology

Incorporates advanced nitrogen generator processes, optimised gas distributors, streamlined adsorber design, and self-compensating cylinder compression technology to ensure low operational costs and reliable performance.

Low Noise

Based on aerodynamic and noise spectrum analysis of PSA equipment, impedance composite silencers are employed alongside premium resistive sound-absorbing materials and robust structural design to effectively eliminate high, medium, and low-frequency noise.

High Automation

Utilises Siemens PLC and configuration software with a user-friendly interface featuring multi-screen display functionality. Online display of valve status, equipment operation, and product nitrogen parameters (purity, flow rate, temperature, dew point) enables unmanned operation. Remote communication with DCS systems is achievable as required.

Internet of Things (IoT) System

Optional IoT functionality facilitates remote monitoring and data analysis via mobile or computer terminals.

Frequently Asked Questions

-

Q1: Are you a manufacturer or trading company? ▼A1: We are professional manufacturer with big modern factory in Shanghai, China. Both OEM & ODM service can be accepted.

-

Q2: Warranty terms of your machine? ▼A2: One year for the whole machine and two years for screw air end, except consumable spare parts. We provide technical support according to your needs.

-

Q3: Will you provide some spare parts of the machines? ▼A3: Yes. We provide spare parts for daily maintenance.

-

Q4: What voltage can you provide? ▼A4: We can support 220V/380V/400V/415V/440V/480V/570V/600V/1000V 50HZ/60HZ. Send your requirements to our sales manager and we will customize it for you.

-

Q5: How long will you take to arrange production? ▼A5: Delivery of standard goods within 7-10 working days, customization takes about 30 days.

-

Q6: How to pay? ▼A6: T/T, L/C, D/P, Western Union, Apple pay, Google pay, PAYPAL, Credit Card and so on. We also accept USD, RMB, EUR and other currencies.

-

Q7: Can you accept OEM/ODM orders? ▼A7: Yes, we have a professional design team, OEM/ODM orders are very welcome.

CN

CN