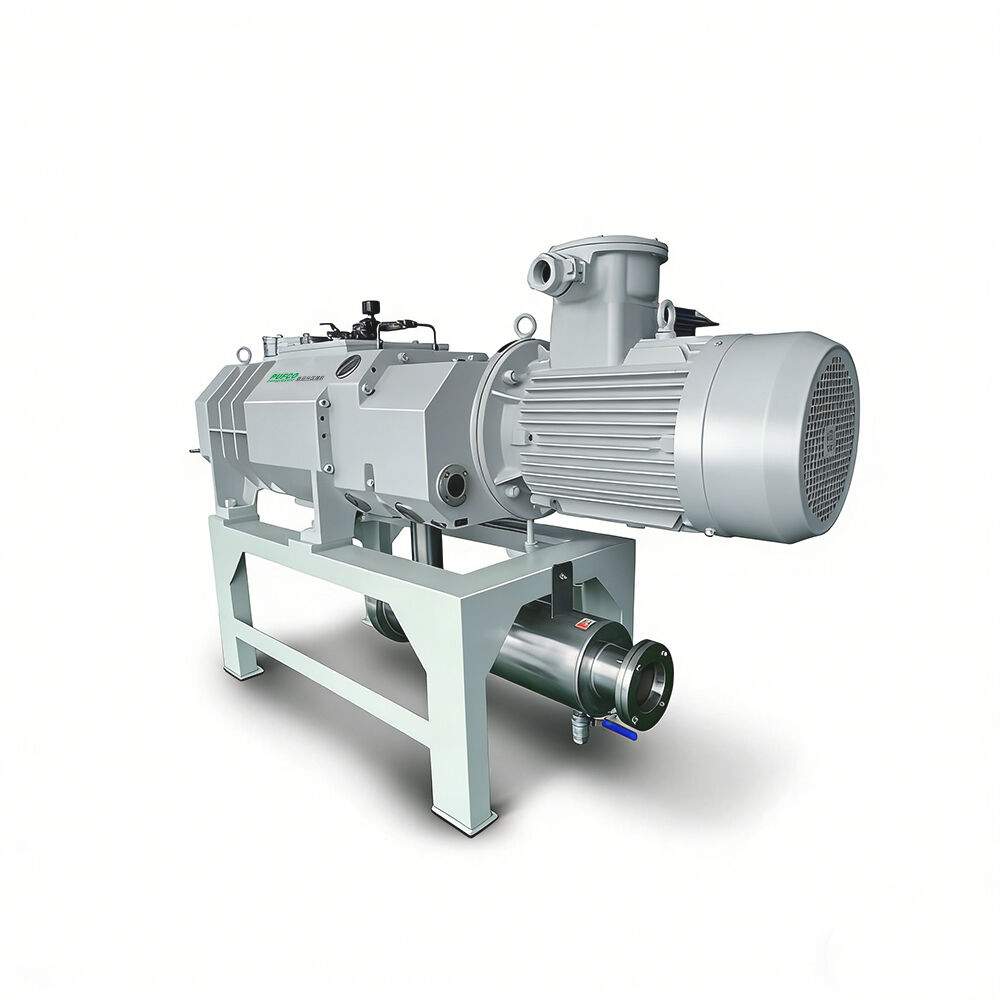

Dry Type Screw Vacuum Pump

1.Uses two synchronously rotating screws operating in opposite directions to generate vacuum suction and exhaust.

2.Precisely balanced screws maintain a fixed clearance, enabling friction-free operation.

3.Delivers stable performance with low noise and vibration.

4.Oil-free working chamber, ensuring clean operation and minimal maintenance.

- Overview

- Product Advantages

- Technical Parameters

- FAQ

A screw vacuum pump utilizes a pair of screws rotating synchronously at high speed in opposite directions within the pump casing to achieve suction and exhaust functions. The two screws are precisely calibrated through dynamic balancing and maintain a specific clearance between each other. Therefore, the pump operates without friction between components, ensuring stable running, low noise levels, and no requirement for lubricating oil in the working chamber.

Oil-Free Cleanliness & Dual Advantages of Cost Efficiency & Safety

Oil-free operation chamber ensures zero-pollution delivery of process gases. High gas recovery rate and easy tail gas treatment significantly reduce operational costs and safety risks.

High-Efficiency Cooling & Lower Energy Consumption

Equipped with jacket cooling technology, the equipment maintains stable operation with only a small amount of circulating cooling water, achieving high cooling efficiency, water conservation and energy saving.

Superior Working Condition Adaptability & Wide Application Scope

Capable of efficiently pumping various complex gases including condensable, corrosive, flammable, explosive, crystallizable and solidifiable types, and easily copes with harsh working environments.

Stable & Reliable Performance & High Operating Efficiency

Adopts multi-stage helical rotors and eliminates the intermediate partition structure, removing middle-stage suction and exhaust processes. The working process is simple, continuous, and greatly improves operational efficiency and stability.

Low Maintenance & Long Service Life of the Whole Unit

The contact-free, wear-free rotors feature a simplified structure with fewer components, facilitating convenient post-maintenance. The equipment also has a low failure rate, effectively extending the service life of the whole unit.

Strong Flexible Compatibility & Versatile Combination Applications

Boasts a wide inlet pressure adaptability range (stable operation from 1 Pa to atmospheric pressure). It can be combined with Roots pumps, molecular pumps and other equipment, and delivers excellent pumping efficiency when used as a forepump.

| Model | Pumping rate (m³/hr) |

Ultimate vacuum(Pa) | Power (kW) |

rotational speed(rpm) | Import(mm) | Export(mm) | cooling water(L/min) | Weight(kg) | Oil(L) | Size (LWH,mm) |

| PDSV180 50Hz | 180 | 2 | 7.5 | 2900 | 65 | 50 | 2.5 | 335 | 0.85 | 1200*400*780 |

| PDSV180 60Hz | 216 | 1 | 7.5 | 3550 | ||||||

| PDSV250 50Hz | 250 | 2 | 7.5 | 2900 | 65 | 50 | 2.5 | 335 | 0.85 | 1200*400*780 |

| PDSV250 60Hz | 300 | 1 | 7.5 | 3550 | ||||||

| PDSV250 50Hz | 250 | 2 | 7.5 | 2900 | 80 | 80 | 2.6 | 345 | 0.85 | 1243*400*780 |

| PDSV250 60Hz | 300 | 1 | 7.5 | 3550 | ||||||

| PDSV400 50Hz | 400 | 2 | 7.5 | 2900 | 80 | 50 | 2.5 | 345 | 0.85 | 1243*400*780 |

| PDSV400 60Hz | 480 | 1 | 11 | 3550 | ||||||

| PDSV400 50Hz | 400 | 2 | 11 | 2900 | 100 | 80 | 2.8 | 610 | 1.4 | 1547*490*1147 |

| PDSV400 60Hz | 480 | 1 | 15 | 3550 | ||||||

| PDSV540 50Hz | 540 | 2 | 18.5 | 2900 | 150 | 80 | 3 | 675 | 2 | 1538*530*1095 |

| PDSV540 60Hz | 650 | 1 | 18.5 | 3550 | ||||||

| PDSV580 50Hz | 580 | 2 | 15 | 2900 | 100 | 80 | 2.6 | 610 | 1.4 | 1547*490*1147 |

| PDSV580 60Hz | 700 | 1 | 15 | 3550 | ||||||

| PDSV720 50Hz | 720 | 2 | 22 | 2900 | 150 | 80 | 4 | 965 | 2 | 1760*600*1200 |

| PDSV720 60Hz | 850 | 1 | 22 | 3550 | ||||||

| PDSV800 50Hz | 800 | 2 | 18.5 | 2900 | 150 | 80 | 2.8 | 675 | 2 | 1538*530*1095 |

| PDSV800 60Hz | 960 | 1 | 22 | 3550 | ||||||

| PDSV1000 50Hz | 1000 | 100 | 22 | 2900 | 150 | 80 | 2.8 | 675 | 2 | 1538*530*1095 |

| PDSV1000 60Hz | 1200 | 200 | 22 | 3550 | ||||||

| PDSV1080 50Hz | 1080 | 50 | 22 | 2900 | 150 | 80 | 2.8 | 675 | 2 | 1538*530*1095 |

| PDSV1080 60Hz | 1290 | 30 | 22 | 3550 | ||||||

| PDSV1080 50Hz | 1080 | 50 | 30 | 2900 | 150 | 100 | 5 | 1000 | 2 | 1760*600*1200 |

| PDSV1080 60Hz | 1290 | 30 | 37 | 3550 | ||||||

| PDSV1200 50Hz | 1200 | 2 | 30 | 2900 | 150 | 100 | 3.5 | 1000 | 2 | 1760*600*1200 |

| PDSV1200 60Hz | 1440 | 1 | 37 | 3550 |

Frequently Asked Questions

-

Q1: Are you a manufacturer or trading company? ▼A1: We are professional manufacturer with big modern factory in Shanghai, China. Both OEM & ODM service can be accepted.

-

Q2: Warranty terms of your machine? ▼A2: One year for the whole machine and two years for screw air end, except consumable spare parts. We provide technical support according to your needs.

-

Q3: Will you provide some spare parts of the machines? ▼A3: Yes. We provide spare parts for daily maintenance.

-

Q4: What voltage can you provide? ▼A4: We can support 220V/380V/400V/415V/440V/480V/570V/600V/1000V 50HZ/60HZ. Send your requirements to our sales manager and we will customize it for you.

-

Q5: How long will you take to arrange production? ▼A5: Delivery of standard goods within 7-10 working days, customization takes about 30 days.

-

Q6: How to pay? ▼A6: T/T, L/C, D/P, Western Union, Apple pay, Google pay, PAYPAL, Credit Card and so on. We also accept USD, RMB, EUR and other currencies.

-

Q7: Can you accept OEM/ODM orders? ▼A7: Yes, we have a professional design team, OEM/ODM orders are very welcome.

CN

CN